PISTON STYLE

These gauges measure pressure drops using precision machined metal piston encapsulated in a PTFE seal. This creates similar seal to a hypodermic needle. Despite the accuracy to which these seals are machined, there is still a small amount of leakage that occurs around the piston. This is why a piston gauge should not be used for liquid level applications or leak detection systems. Instead, they are recommended for filtration systems and flow rate applications.

Advantages of Piston Gauges:

• Lower costs

• Higher temperature capabilities

• Higher-pressure ratings

• Higher differential pressure ranges

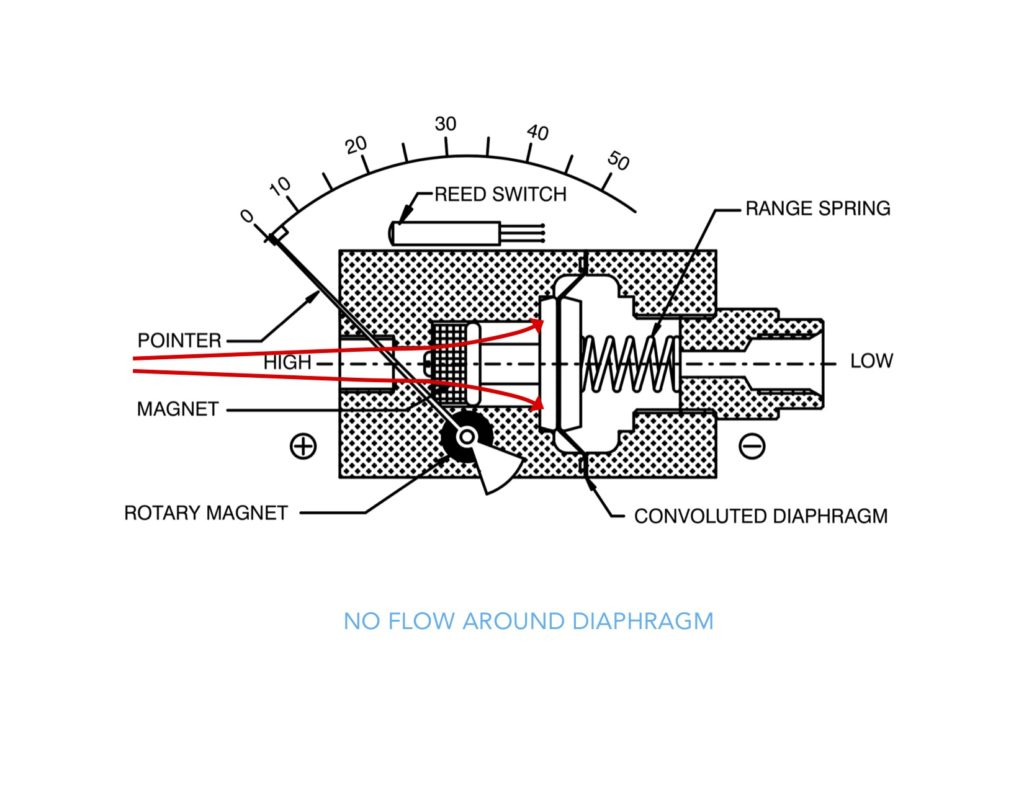

DIAPHRAGM STYLE

This type of gauge utilizes a rubber diaphragm to measure pressure. This creates a perfect barrier through the gauge and allows for zero leakage. Because they create a perfect seal, they are best suited for liquid level applications and leak detection systems. As the diaphragm size increases, the sensing area also increases. This is why larger diaphragms are used on low pressure ranges, such as the 400DGC.

Advantages of Diaphragm Gauges:

• No flow through gauge

• More sensitive measurement

• Lower pressure ranges available

• Can have a zero center dial

Piston Gauges

filterSHIELD

(10, 20, 30 PSID Ranges)

Specifications

- High System Pressure (3000 psi)

- Stocked in 10, 20, 30, and 50PSID range

- Comes with Max pointer and color band

- Great for filter systems, especially carts and skids

Past Generation Equivalents

NA

NA

PG

(3.5-1000 PSID Ranges)

Specifications

- Highest System Pressure (6000 psi)

- Ideal for Liquids

- Great for Filters and Hydraulics

- Lowest Cost Precision Gauge

Past Generation Equivalents

- 200DPG

- DPG200:P

Diaphragam Gauges

DG

(1-60 PSID Ranges)

- 1500 PSI Max

- 2% Accuracy

- Widespread usage in Cryogenic Storage

Past Generation Equivalents

- 300DGC

- DPG200:S

LDG

(1-25″ H2O Ranges)

- System pressure rating (500 psi)

- 2% Accuracy

- Ultra low differential pressure

Past Generation Equivalents

- 400DGC

- DPG200:M

HVG

(1-50″ H2O Ranges)

- Ultra low DP Ranges

- System pressure rating, only 35 psi

- Ideal application is HVAC and flow balancing

Past Generation Equivalents

- 600DGC

- MAGNETIC 600

Commonly Used Accessories

Liquid Filling

Glycerin or silicone dial case fills for reducing vibration and preventing fog buildup.

Color Band

Customizable three color indication at key pressure points in system.

Mounting Brackets

2″ pipe or wall mounting brackets that work with all precision gauges and ease installation.

Dial Sizes

Distributors and manufacturers can choose from a wide variety of dial sizes and options to best meet their compatibility needs

Follower Pointers

Detect pressure peaks throughout the day without needing to always watch the gauge.

Portable Kit

Use one gauge to monitor multiple devices with a portable kit

Electrical Switches

1 or 2 SPST or SPDT switches that can be set and field adjusted to the pressure range.

Filter Head Mount Kits

Hardware can be supplied to directly connect to large bag housings and filter heads