Differential Pressure Plus Inc. has been designing and manufacturing differential pressure gauges in Branford, CT, since 1991. Our applications involve monitoring water and fuel filters and measuring liquid levels in cryogenic tanks.

WHAT WE DO

We manufacture differential pressure gauges for filter, cryogenic storage, pump, and flow control applications around the world.

OUR SPECIALTY

DPP’s customizable line of differential pressure gauges and filter indicators are applied to a wide variety of applications.

OUR PASSION

Helping manufacturers around the world develop new and innovative solutions to improve their product and process systems through the implementation of differential pressure measurement.

HOW WE ARE DIFFERENT

Our staff is a blend of young innovative minds and experienced engineers that are constantly looking to the future. The three pillars to our success are customer service, on time delivery, and affordability.

worldwide customers

PRESSURE RANGES

YEARS OF EXPERIENCE

SITE VIEWS LAST MONTH

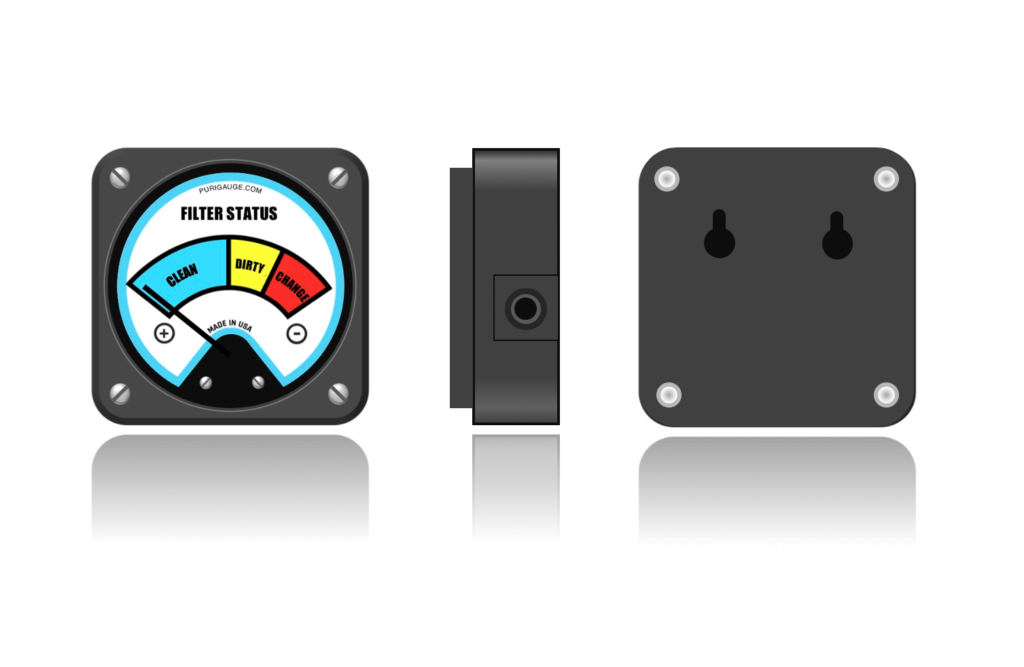

MODULAR FILTER INDICATORS

Our filter indicators can mount directly onto a filter head or be piped to remotely. Their interchangeable parts allow for different ranges, electrical options, and more. Engineers use them to help inform operators what the status of their filter system is.

PRECISION Differential GAUGES

These gauges are used in applications such as filtration, cryogenic level, flow measurement, and much more. The precision differential pressure gauges are trusted by thousands of manufacturers around the world.

KITS AND LAB EQUIPMENT

For backflow testings and portable flow monitoring kits. These specially designed pieces of equipment are engineered to be the best in the industry. We can design a custom case, includes hoses and fittings, and just about anything else to make the gauge ideal for your application

Differential Pressure Gauge Applications

Differential pressure gauges are some of the most underutilized and misunderstood products in manufacturing. As a result of a near complete lack of mention from engineering eduction, we see engineers constantly using two standard pressure gauges, when they could just use one differential pressure gauge. From applications involving filtration system, measuring flow rates using the Bernoulli Principle, displaying liquid levels in cryogenic tanks, detecting leaks in systems, and so much more, these capable instruments should be part of every engineer’s toolbox.

What is a Differential Pressure Gauge

Simply put, a differential pressure gauge measures the difference in pressure between two connections. Let’s imagine an application where you have a tank at 100 psi and another at 95 psi. If you connect a differential pressure gauge between those two tanks, you will read 5 psi.

There are a few different gauge designs to achieve this. Differential Pressure Plus utilizes a design known as a “Magnetic Coupling.” Each gauge has a magnetic piston that moves back and forth like a sea-saw depending on the differential pressure. As a result, the linear movement of this magnetic piston pushes and pulls on a rotary magnet that connects to the pointer. This “magnetic rack and pinion” provide the readout.

Monitoring Filters

As filter cartridges get clogged, the differential pressure between the inlet and outlet increases. This is a result of the buildup of contaminants in the filter mesh. Operators can measure a differential pressure drop across a filter and can get a visual indication about how dirty their filter systems are. As a result, using a differential pressure gauges for a filter application can:

- Help operators prevent damage to their system because they stay informed of filter status.

- Prevent legal issues between filter manufacturers and customers who over exert the life of their filters and misuse the systems

- Increase filter cartridge sales by 20-30% by helping customers stay informed of the filter’s status

- Help distinguish your filter from the 1,000’s of competitors out there

The New Purigauge

PURIGAUGE is the ideal way to monitor home water filter systems. By connecting the upstream side of your filter to the high pressure port and the downstream to the low port, you can get a clear view of the status of your filter cartridge. The integrated John Guest 1/4″ push connect fittings allow for quick plumbing and provide technicians with more installation options than any other gauge on the market! This simple yet effective differential pressure gauge, provides end users with an affordable option to maintain their systems. Also, if you are an OEM, we offer special high volume packaging and pricing options! Email us today to learn more.

Featured in “Practical Engineering”

Check out our new filterSHIELD series gauge in “Practical Engineering’s” recent video about cavitation!

Quick Buying Options

Select models of our differential pressure gauges and filter status indicators are now available on Amazon.com! We understand that sometimes you just want to try out a model and not have to go through a complicated purchasing process. Maybe you also find yourself buying the same gauge over and over. In these cases, check out our Amazon account and see if there’s something close to what you need. Otherwise, we happy to custom build a model for your exact requirements.

Need A Quote?

We would love to help you develop a solution for your application. After supplying us with your requirements, we will have an engineer contact you directly and give you advise and develop pricing in one step