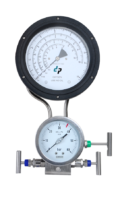

Differential Pressure Gauges

These gauges are used in applications such as filter monitoring, cryogenic level, and flow measurement. These precision differential pressure gauges are trusted by thousands of manufacturers around the world and relied upon for their accuracy.

Filter Status Indicators

Our filter status indicators can mount directly onto a filter head or be piped to remotely. Their interchangeable parts allow for a variety of ranges, electrical options, and mounting configurations. Never forget to change your filter again!

HVAC Systems Gauges

Need to measure ultra low differential pressure, standard pressure, or vacuum? Our HVG has ranges down to 0.5″ H2O, has electrical switch options, is low cost, and a variety of other great options perfect for air handling applications.

Amazon Shop Inventory

Differential Pressure Plus now carries a variety of gauges on our Amazon Prime store. This is a great place to get something quick for testing or if you tend to buy products that fall in our standardized system.

New Designs Developments

Differential Pressure Plus has some exciting new products coming. Our latest collaboration with John Guest Inc. resulted in the world’s first pressure gauge to directly incorporate push connect fittings. The new Purigauge is sure to a great addition.

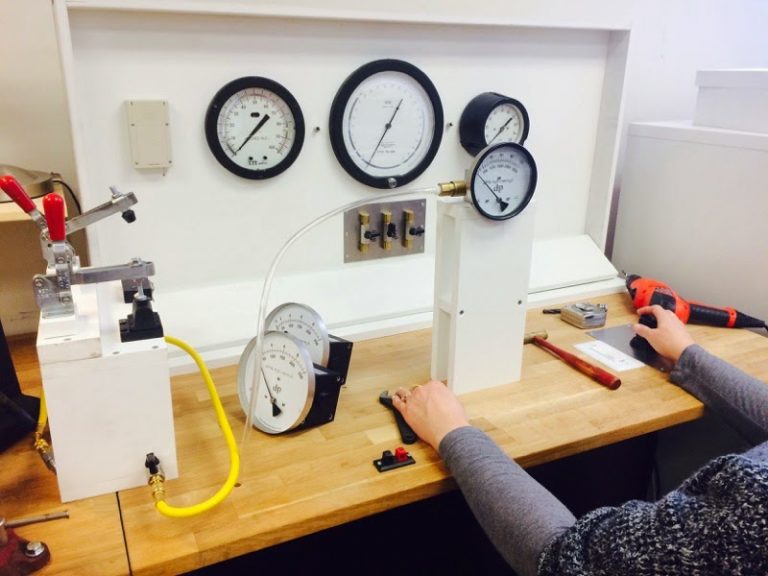

Custom Built Projects

From backflow testing, manifold instals, portable flow monitoring kits. We can create specially designed pieces of equipment for your industry. We can design custom cases, preinstall cooling towers, and just about anything else you need.